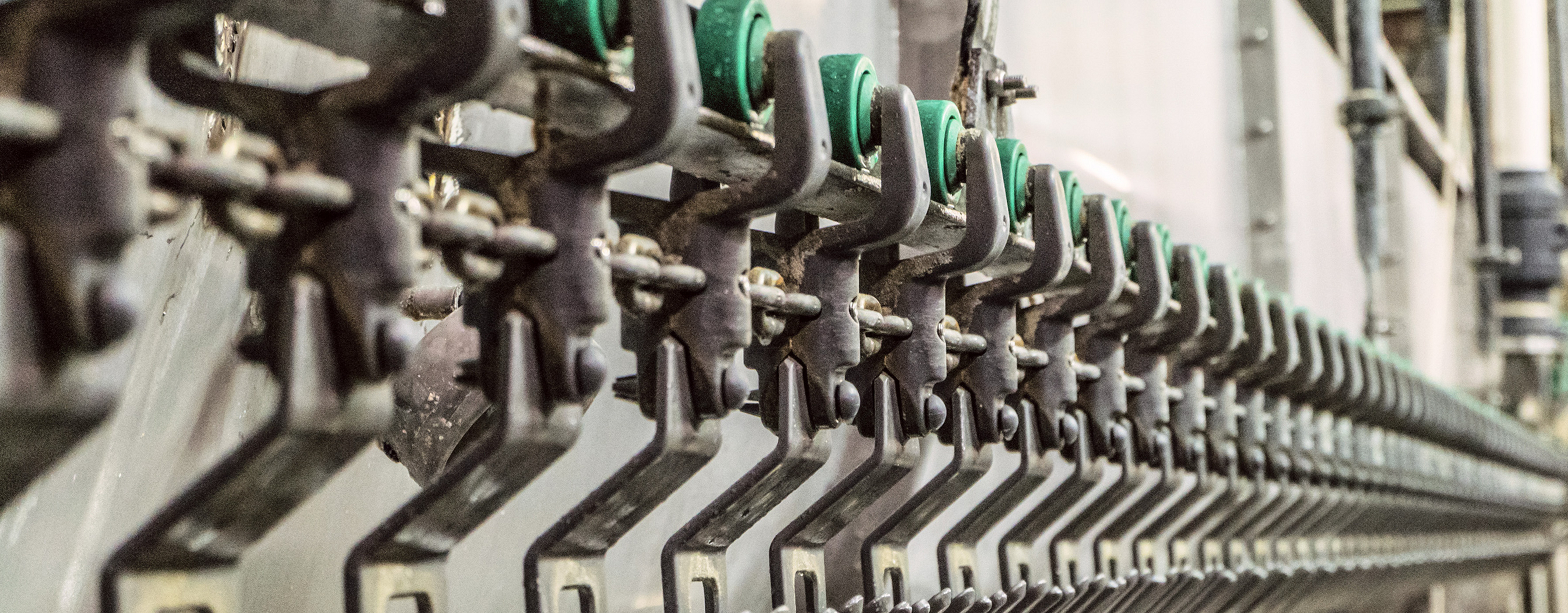

High-quality hoist chains and accessories

All hoist chains, sling chains and the corresponding accessories are tested, certified and bear the H-stamping as proof of quality in accordance with DIN 685. Our customers trust the special product quality and reliable chain properties.

When it comes to durability and corrosion resistance, we are the specialized manufacturer of stainless steel chains.

Röttgers Ketten has been authorised to use the international stainless steel trademark since 1958.

Stainless steel

Stainless steel and rustproof stainless steel have a chromium content of at least 10.5 %. Stainless is not synonymous with never rusting. In aggressive environmental conditions, stainless steel will also oxidise (rust). The French term INOX (inoxydable = stainless) is derived from the term oxidising.

The term stainless steel alone is not to be equated with rustproof stainless steel. It only characterises steels of particular purity and quality. Designations such as V2A, V4A and Nirosta are brand names of companies.

Quality

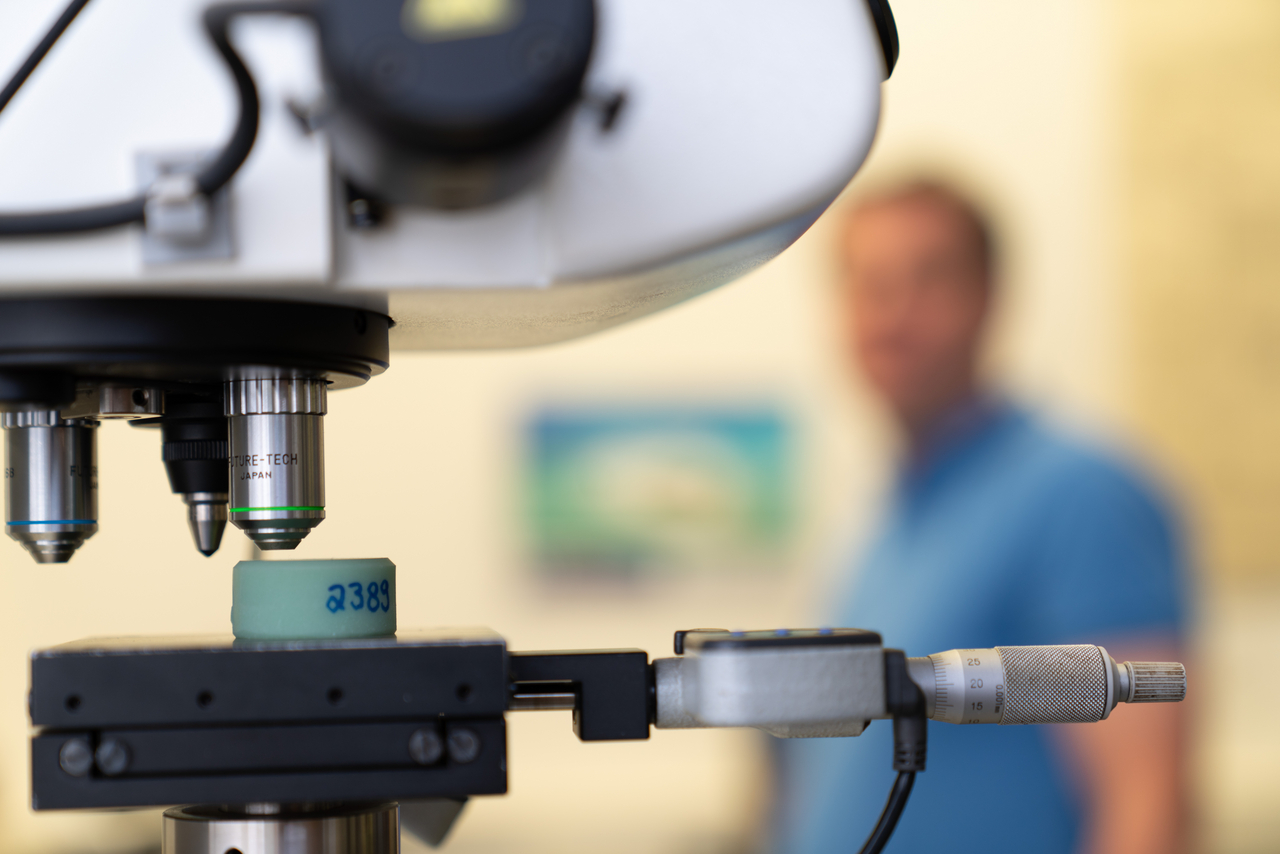

Qualified employees and our modern, well-equipped quality assurance laboratory play a key role in our internal monitoring and therefore make a significant contribution to our process reliability:

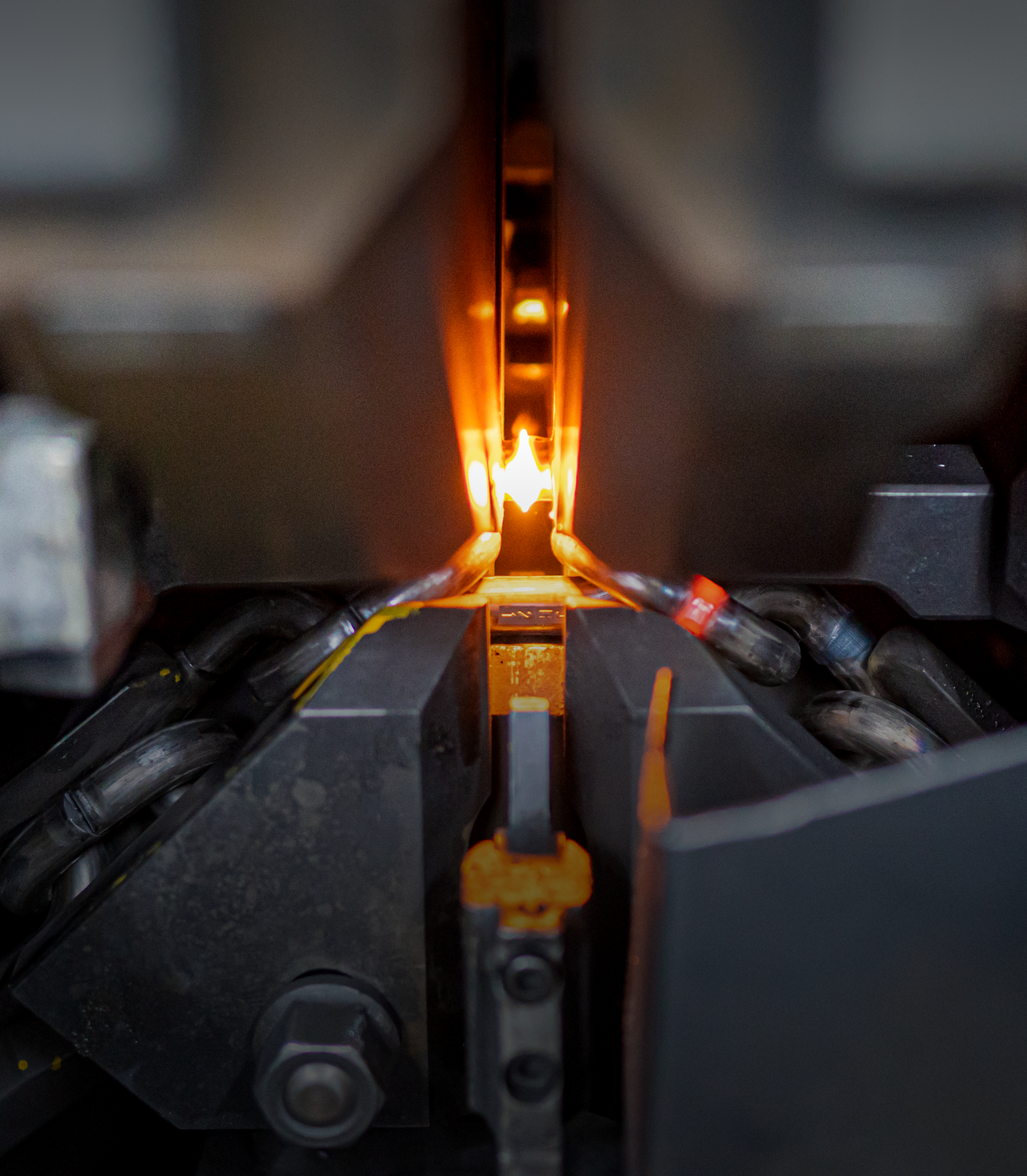

- through the creation of tensile samples

- through tensile tests up to 750 kN

- through preparations

- through hardness tests

- through corrosion tests

- and microscopies including final analyses

Röttgers Ketten has been ISO 9001 certified since 1998. The ISO 9001 certificate proves that all internal company processes comply with the international standard for quality management systems. It also emphasises our commitment to customer satisfaction and our commitment to quality. Our quality management system is based on conviction and a sense of responsibility to the highest standards.

To meet the high requirements placed on our products, we take quality assurance measures that are based on the high standards of the industry. This also means that we as a company are committed to a continuous, sustainable improvement process. This becomes visible through the inner attitude of all employees and permeates all activities in our company. The continuous improvement process relates to our process, product and service quality and is an essential and indispensable part of our quality management system. The traceability and allocation of relevant products and documentation is a matter of course for a functioning quality management system. In the area of round steel chains for lifting purposes, the Machinery Directive 2006/42/EC also applies, which, among other things, regulates a standardised level of protection for accident prevention for machinery within the European Economic Area (EEA).