Stainless steel anchor chains

ROXMA stainless steel anchor chains reach a new level in terms of durability, tensile strength and corrosion resistance and far exceed all current standards. Thanks to the balanced mixed structure of the duplex steel, ROXMA anchor chain offers a strong combination of strength and corrosion resistance.

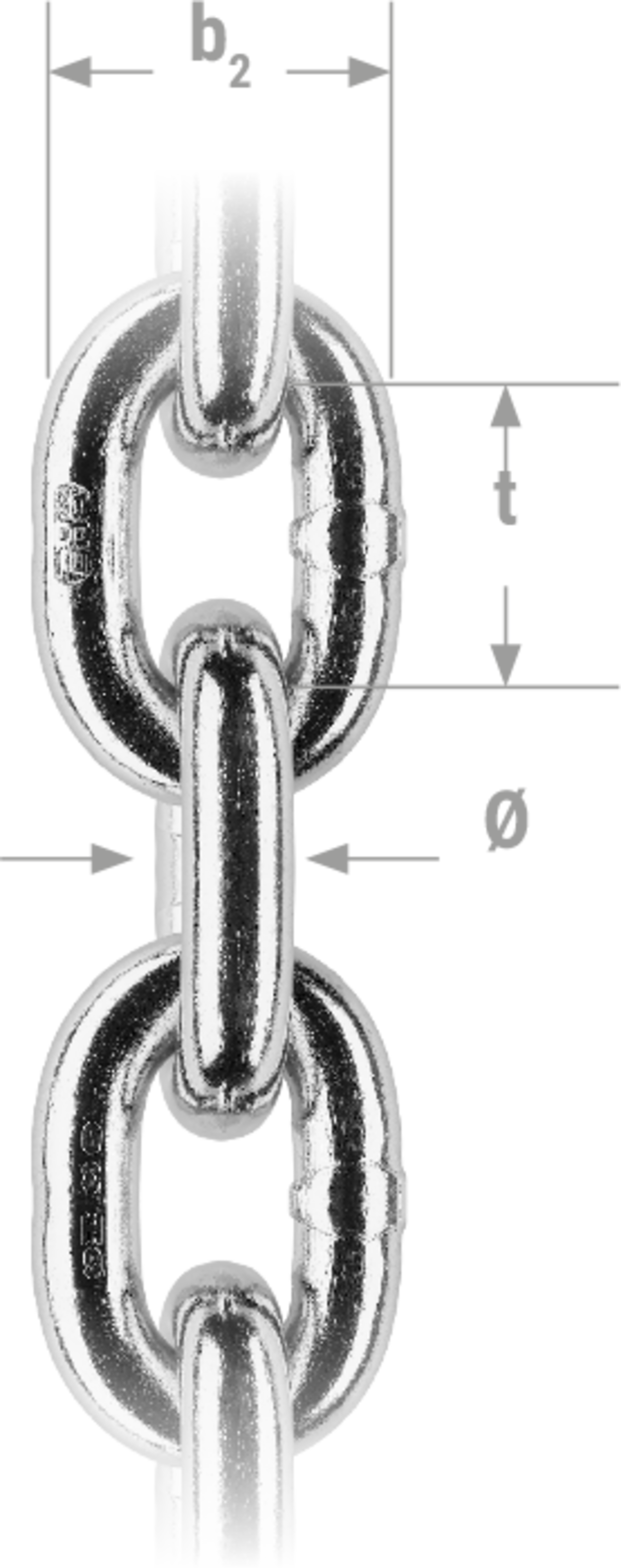

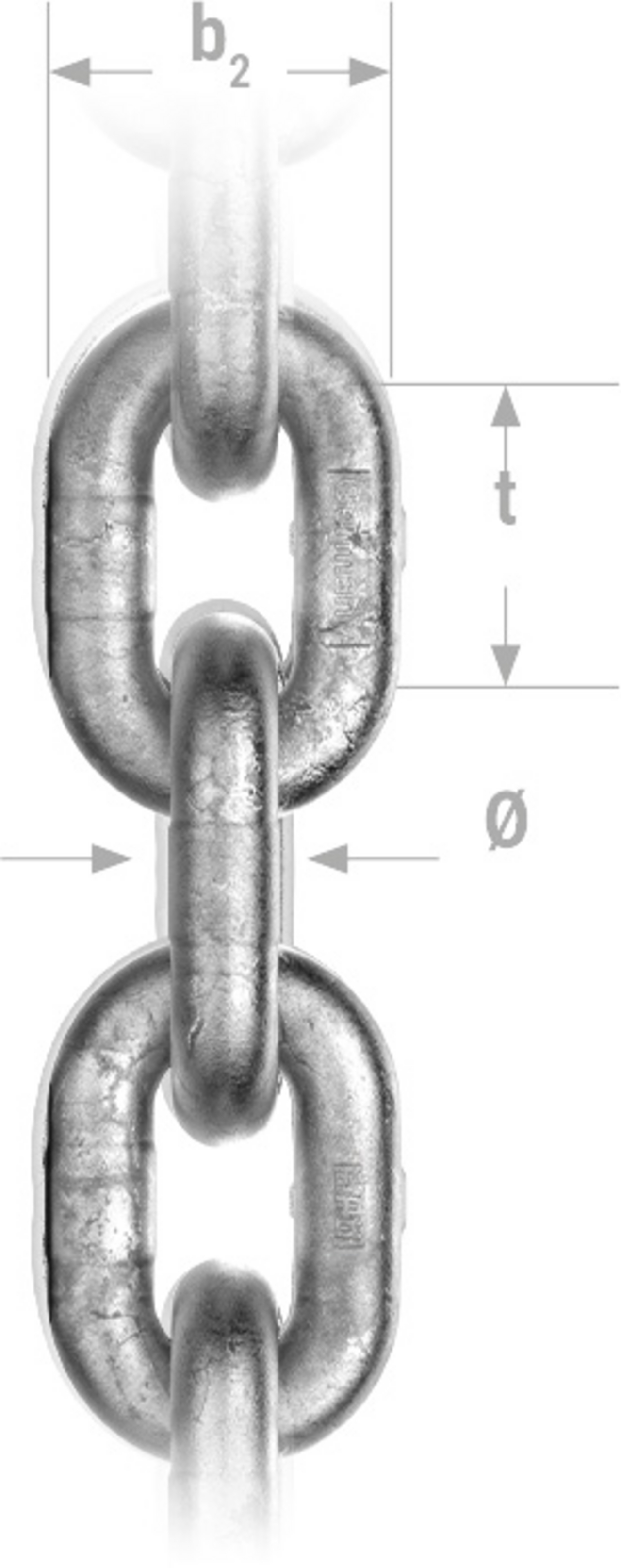

To ensure smooth running in the winch, all ROXMA anchor chains are calibrated to an accuracy of tenths of a millimetre. To protect them from the harsh environment at sea, they are given a very elaborate surface finish as standard. This guarantees the outstanding durability of ROXMA products.

| Item no. A4L | Item no. Duplex | ⌀ | t | b2 | similar standard | Breaking load A4L | Breaking load Duplex |

|---|---|---|---|---|---|---|---|

| RXSD6L | RXSD6LN | 6 | 18,5 | 20 | DIN 766 | 3000 kg | 3850 kg |

| RXSD8L | RXSD8LN | 8 | 24 | 26 | DIN 766 | 5300 kg | 6700 kg |

| RXSD10L | RXSD10LN | 10 | 28 | 34 | DIN 766 | 8500 kg | 10800 kg |

| RXSD13L | RXSD13LN | 13 | 36 | 44 | DIN 766 | 12500 kg | 18000 kg |

| RXSD14L | RXSD14LN | 14 | 41 | 50 | DIN 766 | 15400 kg | 21000 kg |

| RXSD16L | RXSD16LN | 16 | 45 | 53 | DIN 766 | 20000 kg | 26000 kg |

| RXSI6L | RXSI6LN | 6 | 18 | 20,9 | ISO 4565 | 3000 kg | 3850 kg |

| RXSI8L | RXSI8LN | 8 | 24 | 27,8 | ISO 4565 | 5300 kg | 6700 kg |

| RXSI10L | RXSI10LN | 10 | 30 | 35 | ISO 4565 | 8500 kg | 10800 kg |

| RXSI12L | RXSI12LN | 12 | 36 | 42 | ISO 4565 | 11300 kg | 14000 kg |

| RXSI16L | RXSI16LN | 16 | 48 | 54 | EN 818 | 20000 kg | 26000 kg |

Electropolishing €3.10/kg (non-discountable) – up to a bundle length of 70 m | |||||||

Hot-dipped galvanized ROXMA anchor chains are ideal for use in colder waters. The anchor chains are bent and welded from selected chain steels on state-of-the-art equipment. This enables us to guarantee the highest processing quality. Subsequently

the ROXMA chains are tempered in a modern and fully automated multi-purpose chamber furnace line. Targeted heat treatment optimises the mechanical properties of the chain.

As a final step, the ROXMA anchor chains are given a clean and optimum hot-dip galvanisation.

| Item no. Grade 70 | ⌀ | t | b2 | similar standard | Breaking load Grade 70 |

|---|---|---|---|---|---|

| RXGD670 | 6 | 18,5 | 20 | DIN 766 | 3960 kg |

| RXGD870 | 8 | 24 | 26 | DIN 766 | 7100 kg |

| RXGD1070 | 10 | 28 | 34 | DIN 766 | 11200 kg |

| RXGD1370 | 13 | 36 | 44 | DIN 766 | 19000 kg |

| RXGD1670 | 16 | 45 | 53 | DIN 766 | 28200 kg |

| RXGI679 | 6 | 18 | 20,9 | ISO 4565 | 3960 kg |

| RXGI670 | 8 | 24 | 27,8 | ISO 4565 | 7100 kg |

| RXGI1070 | 10 | 30 | 35 | ISO 4565 | 11200 kg |

| RXGI1270 | 12 | 36 | 42 | ISO 4565 | 16000 kg |

Other dimensions available on request: ⌀ 3-18mm | |||||

Quality promise

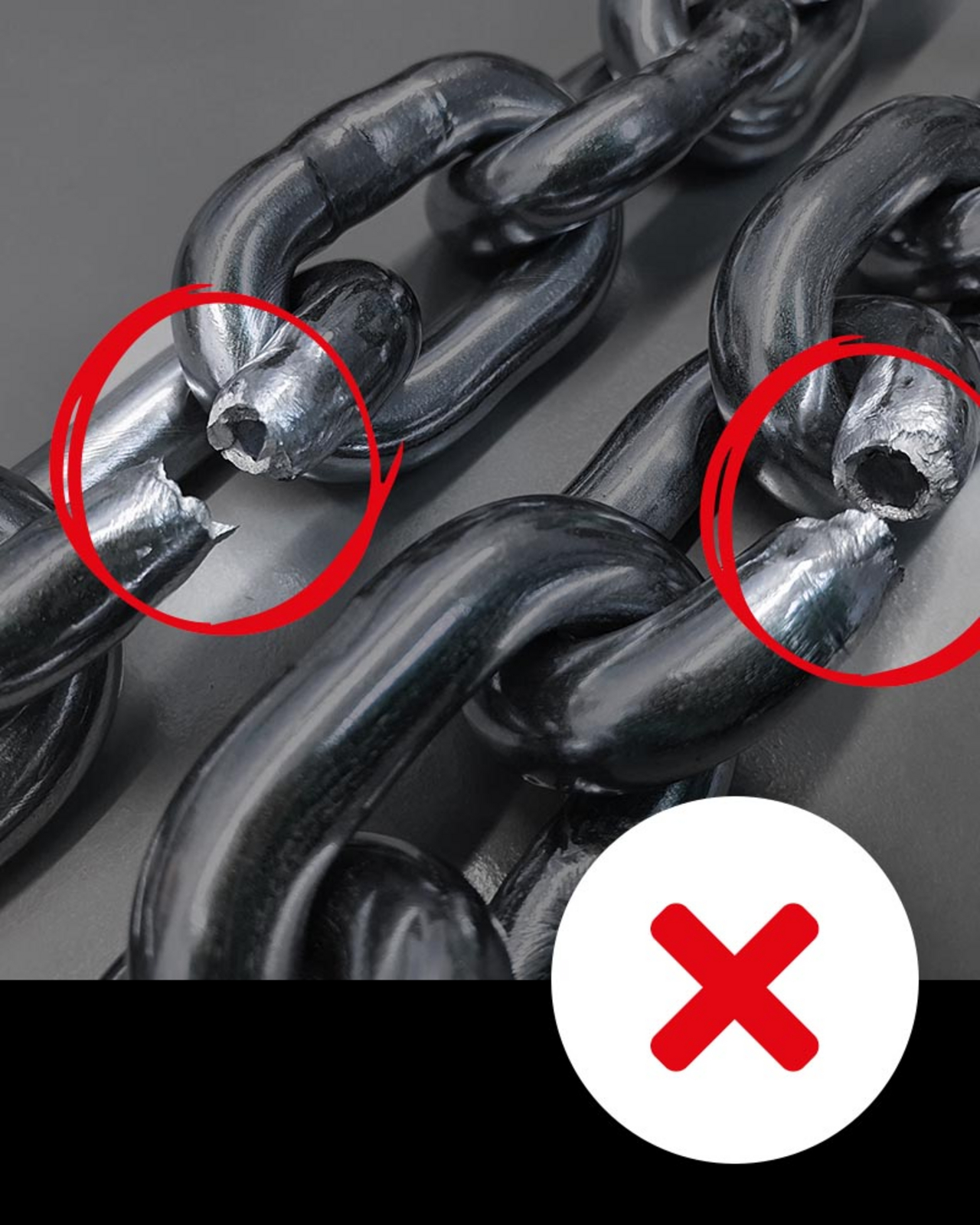

The quality of ROXMA anchor chains is extensively tested in our own laboratory for each production run. In addition to tensile tests, this also includes microscopic cross-sectional analyses.

We are also one of the few anchor chain manufacturers with our own salt spray chamber. There, our ROXMA anchor chains are subjected to months of endurance testing for susceptibility to corrosion under extreme conditions.

A detailed comparative test between our ROXMA anchor chain and a cheap stainless steel chain from Asian production is available for download as a PDF.

Pickled and glossy passivated as standard

Ferritic and non-metallic microparticles can be the starting point for corrosion in untreated stainless steel, as they prevent the complete formation of the passive layer. A pickled and bright passivated surface eliminates this source of defects.

All residues on the surface are removed in the pickling process. The surface is then passivated with a glossy finish. This creates a seamless passive layer in a controlled process.

The corrosion resistance is therefore significantly higher.